Introduction

MIS PSystem is intended for use by enterprises and production units producing advertising printing, books and magazines, packaging (flexible and cardboard), labels and souvenirs, and other types of products using any type of equipment.

The main functions are operational management of the main production and business processes of a printing house, management accounting, analysis of the results of production activities.

- Automates management and accounting functions of a printing order full production cycle from receiving a preliminary application to shipping finished products, as well as production and resource management;

- Functions within the framework of an arbitrarily complex organizational and production structure of the enterprise, provides a common information space for geographically remote production and commercial units, as well as a group of enterprises included in a single business process;

- Provides a description and calculation of a printing order of any complexity;

- Supports the description of any production processes of a printing company: prepress, sheet and web printing (including flexo), bookbinding and finishing processes;

- Automates the work a printing company warehouses, including the one of finished products, implements the functions of reserving materials and automating purchases;

- The system delivery package includes the work of a specialist to facilitate the system installation on the customer’s equipment and the system individual configuration, which allows you to build computer management and accounting at your enterprise in the shortest possible time.

PSystem implements typical business processes that exist in most printing companies:

The system operates in client-server mode and ensures stable performance regardless of the number of connected workstations. The number of workstations is not limited

PSystem allows you to:

- calculate the price and cost-price of an order, the standard time your production operations take, as well as the need for basic materials and paper;

- monitor all stages of order fulfillment, from receiving an order layout from a client to shipping finished products;

- register business transactions for the sale of finished products in any currency and track the status of settlements with clients;

- plan equipment loading and estimate the time each stage of the technological process takes;

- plan the need for materials and paper and track their timely preparation;

- manage the order production process, promptly adjust the technological route and parameters of technological operations while assessing the impact of technology changes on the cost-price of the order;

- record the parameters of the order’s passage along the technological route and the actual resources consumption;

- analyze the results of the enterprise’s production and commercial activities;

- exchange data with various external systems.

Order Portfolio

MIS PSystem allows you to organize and manage:

- Fast oredering procedure

- Order estimation and profit planing

- Fast document creation

- Client resours management

- Client settelment management

- Business analysis.

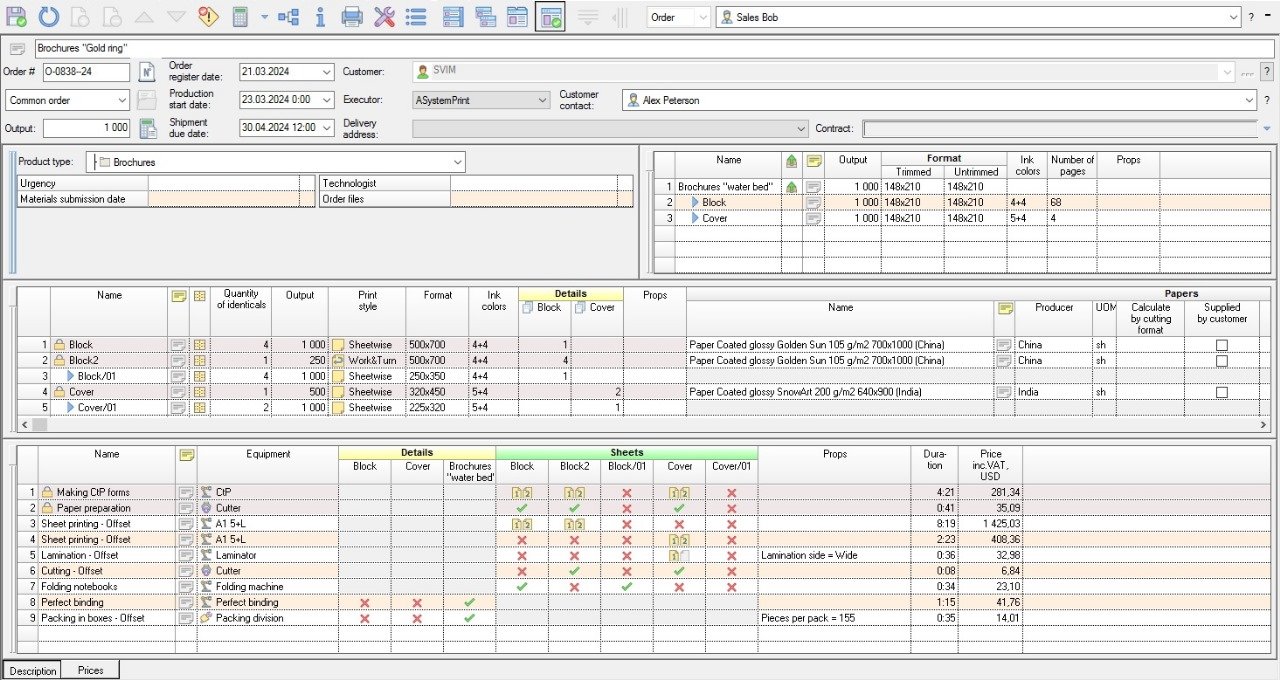

Placing and calculation of the printing order

The system provides several modes for placing an order:

- using the wizard for placing standard orders (the mode is intended for the sales manager and ensures very fast order placement by filling in/correcting the requested parameters and answering simple questions);

- by template (a library of templates is used, from which a sample is loaded, which can then be edited and calculated);

- by sample (any order registered in the system can be used as a template for a new order);

- full description (the order description is made “from scratch”; the mode is used by the technologist to describe non-standard products);

- the procedure for placing orders using the wizard does not require the user to know the technology of printing production and is available to the sales manager after a short training.

The result of any of the proposed processing modes is a complete technological description of the work, a step-by-step calculation of the price and planned cost-price of the order; calculation of the consumption of all types of paper and basic materials which are specified in the order description; calculation of the standard time of all production processes.

The estimated amount of paper and basic materials can be reserved in the warehouse directly during the order processing.

All manual adjustments to the quantitative and cost indicators entered into the calculation are registered by the system and displayed as discounts and markups in relation to the estimated indicators. The system allows you to take into account the commission fee and other custom cost items.

The registered orders are presented in the system as a table, which columns can display any order details (No., customer, name, output quantity, type, price, cost-price, manager, delivery date), as well as the status of settlements for each order.

Preparation of production documentation

One of the results of calculating and placing an order is a package of production documentation, including:

- Order technology sheet;

- Requisition for paper and materials;

- Application for subcontracting works;

- Paper waste detail leaf;

- Order costs detail leaf;

- Assignment to colorist.

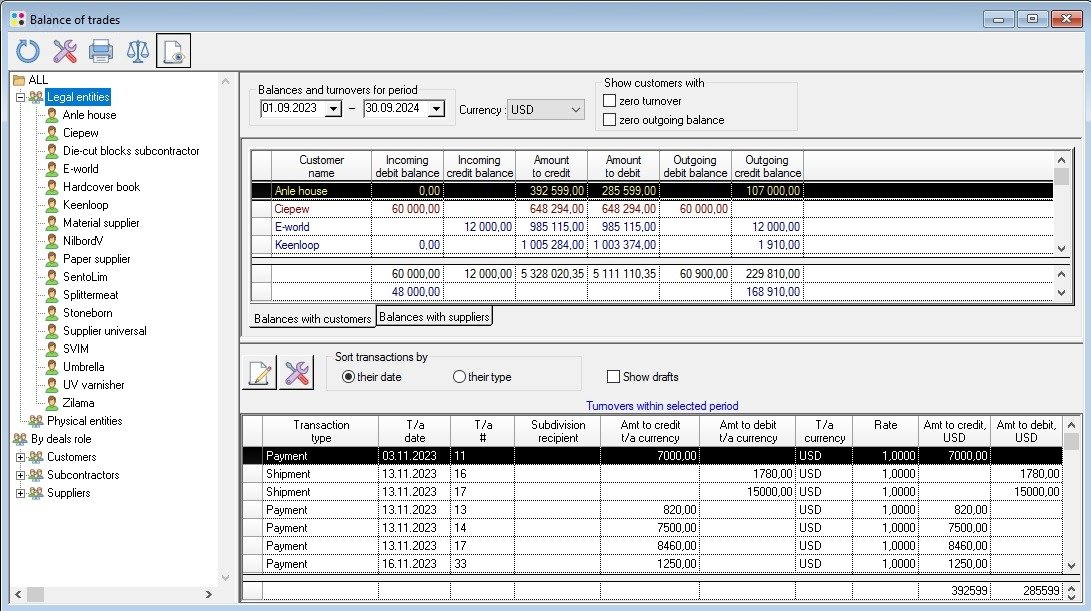

Settlements with customers, preparation of payment

and shipping documents

PSystem, based on the results of order calculation, allows you to automatically generate a contract for the provision of printing services and a commercial offer to the customer.

MIS ensures the preparation of settlement and shipping documents, including:

- Issuing an invoice for order payment;

- Registration of receipt of payment;

- Preparation of shipping documents (consignment note, bill of lading and invoice). Settlement and shipping documents can be exported to the enterprise accounting system.

- Settlement and shipping documents can be registered in any currency with recalculation at the cross rate.

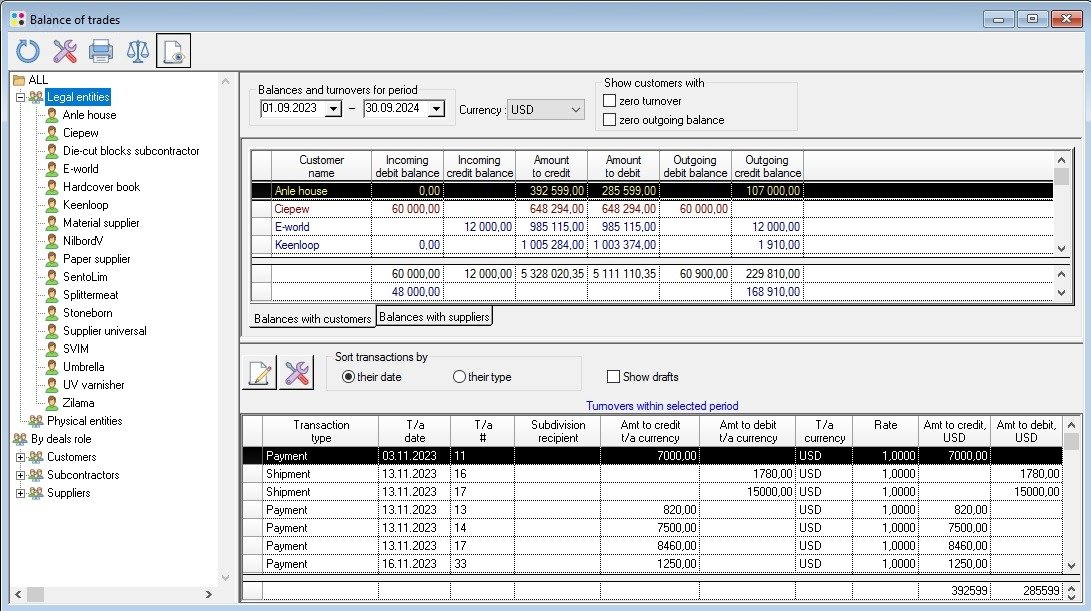

MIS PSystem provides accounting of mutual settlements, both in terms of customers and in terms of individual orders. The system promptly provides data on the current balance of mutual settlements, on turnover for the period, deciphers turnover by individual documents.

Information on customers is stored in the system’s customer directory. The system supports a set of arbitrary independent classifiers of counterparties, as well as individual sets of details for each group.

MIS provides storage of the following types of data on a counterparty:

- identity and description details and classification;

- directory of contracts;

- directory of bank accounts;

- directory of contact persons of the counterparty;

- list of business transactions and the current state of mutual settlements.

The customer directory is displayed as a table with a customizable set of columns containing details.

Convenient access to information is provided by:

- classifiers;

- filtering function according to user-defined conditions;

- search function.

Production Management (ERP)

MIS Psystem supports the following functionality:

- Enterprise resource planning

- Enterprise resource optimization

- Technology process control

- Production personal control

- Quality control

- Production and technology processes analysis

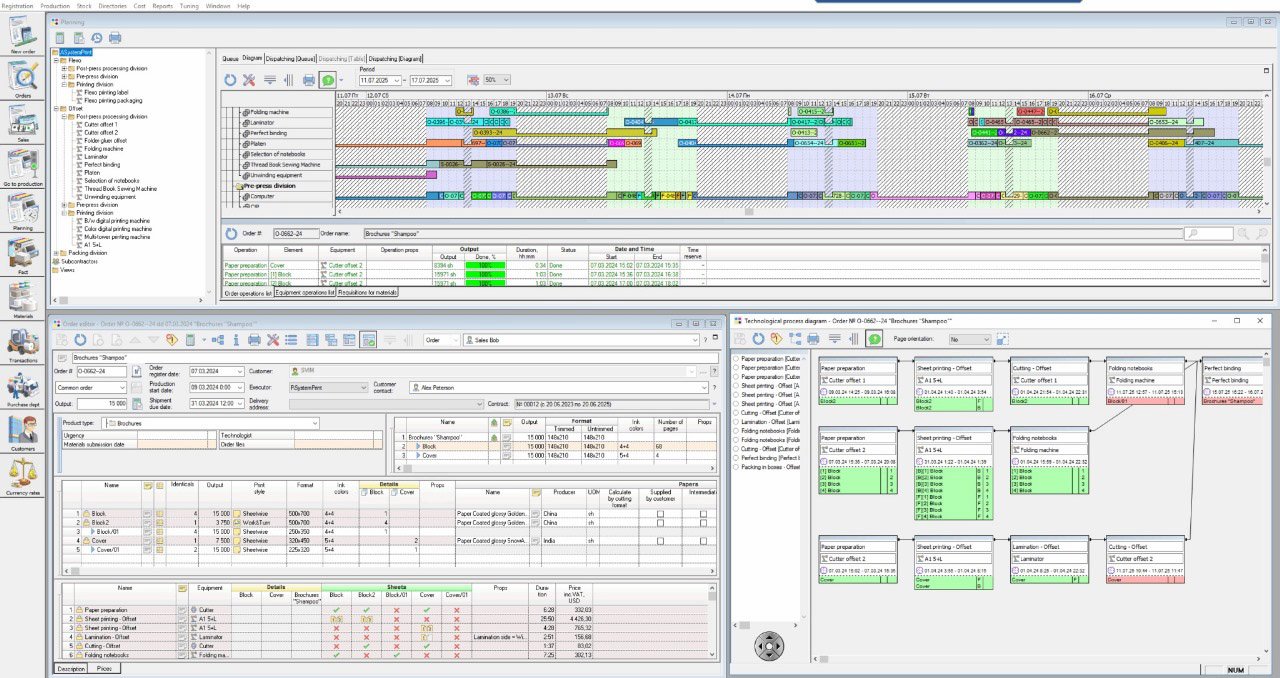

Production planning and dispatching

The technological route of any order, during the registration process, is described by a technological process diagram, which determines the sequence of operations and the possibility of parallelizing individual fragments of the technological process.

The duration of operations is determined based on the results of the order calculation. Here, time lags between successive operations are automatically determined, which allow for the possibility of starting an operation without waiting for the end of the previous one, or an additional technological time lag between adjacent operations.

When automatically building a plan, the equipment operation schedule and standard time costs for transferring intermediates between departments are taken into account.

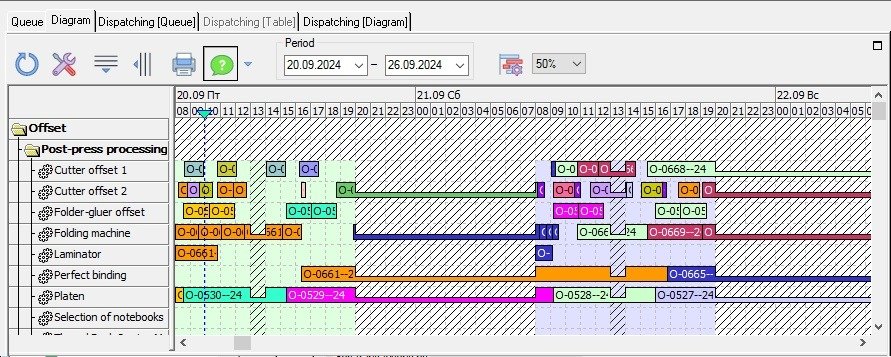

Orders are placed in the production plan according the option controlled by the user. When included in the production plan, the user selects an algorithm (“as early as possible”, “from the delivery date” or “to the end of the queue”), as well as the order priority, which controls the sequence of placing orders in the plan. The overall picture of equipment loading is displayed on the Gantt chart.

Queue management is performed in dispatching mode. The dispatching mode implements the following functions:

- changing the order of operations in a queue;

- moving an operation from machine to machine;

- locking an operation by time;

- locking the sequence of operations at the beginning of the queue;

- adjusting the duration of an operation;

- splitting a scheduled operation and adding unscheduled operations;

- adjusting process parameters;

- planning idle times.

In dispatching mode, each change made by the user is accompanied by an automatic recalculation of the start time and duration of operations. The system promptly signals any conflicts that arise, which can be resolved manually or automatically, when the plan is recalculated.

After registering the completion of an operation, it disappears from the corresponding queue, while the completion time of the operation is automatically taken into account for adjusting the plan.

Production accounting

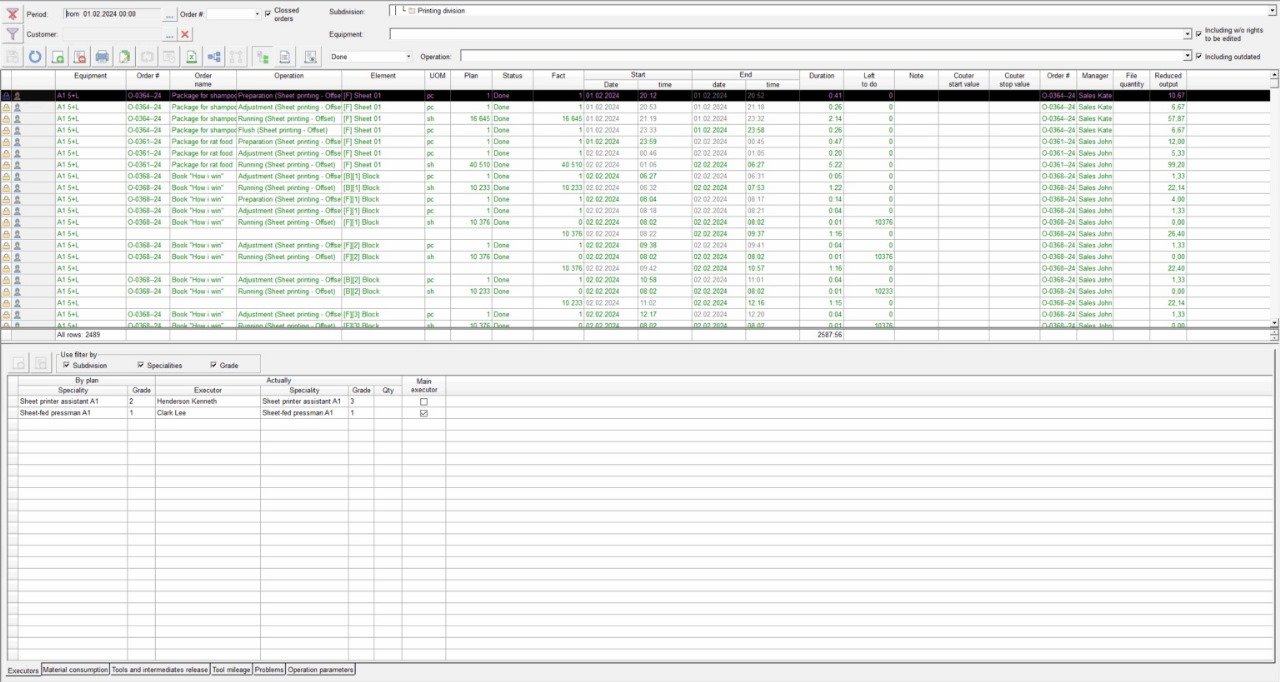

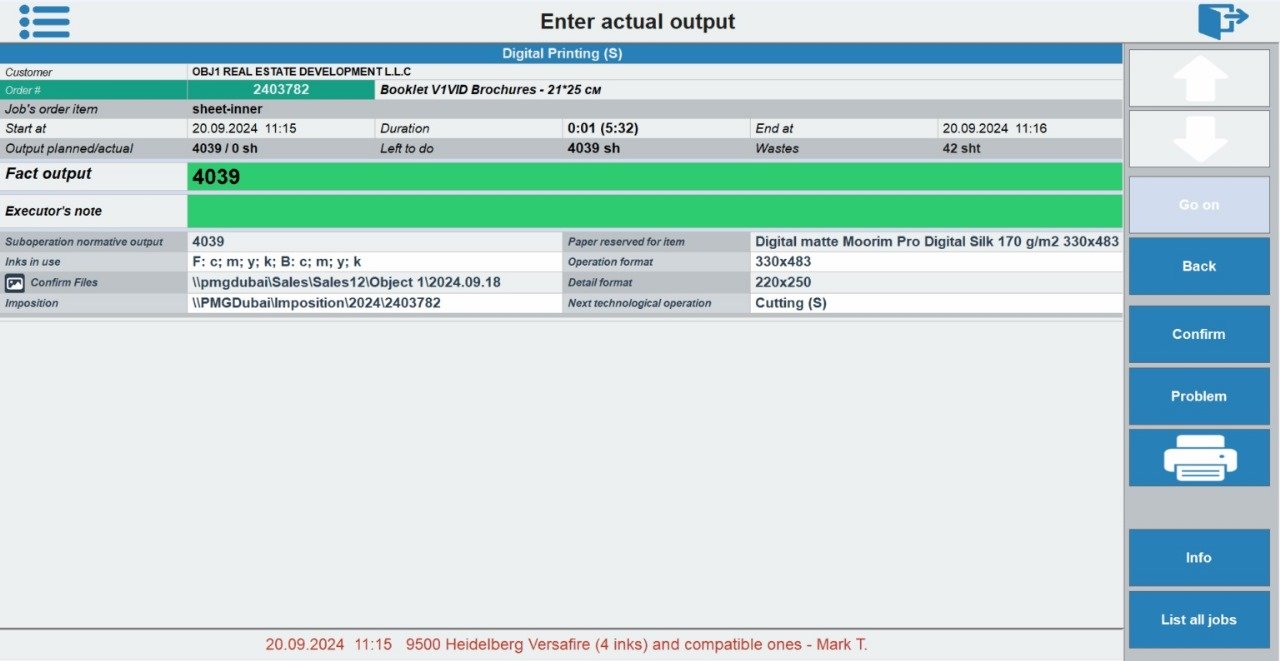

The production accounting subsystem allows you to register both full and partial completion of a process operation, the execution of unscheduled operations, and register unplanned idle times.

All information on the actual performance of production tasks is promptly displayed in the dispatching mode and is taken into account when recalculating the plan.

The process of production accounting provides for the input of the following information:

- date/time of the operation start;

- date/time of the operation end;

- actual output quantity;

- executors;

- actual material consumption;

- actual paper consumption and unscheduled technical waste.

Emergency issues and stops are registered with an indication of the cause and effect – repeated execution or removal of the operation.

Information on the registered consumption of materials and paper is automatically transferred to the warehouse accounting subsystem.

Registration of actual performance can be performed both from the dispatching mode and through several specialized interfaces oriented both to centralized registration and to data entry by the executors directly at their workplace.

Supply and stock management

PSystem functional options:

- Materials stock management

- Suply control

- Reliable remining and turnover management

- Multi-warehouses support

- Material consumption planning

- Remininig and turnover analysis

- Final goods stock management

Material consumption planning material reservation

Requisitions for materials, generated automatically when placing orders or entered manually, are sent to the inventory management subsystem. Based on requests, the system automatically reserves available warehouse balances or, in case of materials lack at warehouses, generates orders to suppliers.

PSystem tracks the state of mutual settlements with suppliers and subcontractors, including:

- generating orders for the supply of materials and paper;

- registering incoming invoices from the supplier;

- registering payment for paper and materials;

- registering the receipt of materials at warehouses.

After the materials have been received at the warehouse, the system can automatically reserve materials for pending requests.

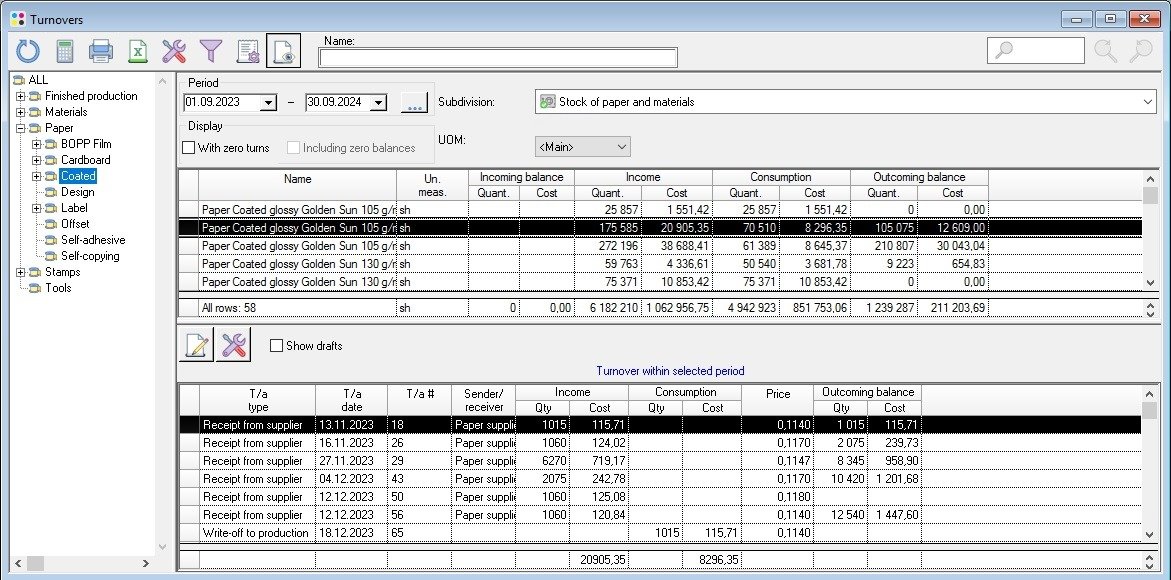

Paper and material accounting

The PSystem warehouse accounting subsystem allows you to account for the presence and movement of production stocks at a printing company. The structure of warehouse facilities and storage locations of any complexity is supported.

Warehouse accounting functions include:

- maintaining stock items directory;

- entering/editing opening balances;

- recording material movements and transformations;

- promptly receiving information on the presence and movement of production stock items by any sections.

The PSystem warehouse accounting subsystem implements a number of unique functions aimed at a printing company:

- arbitrary classification of production stocks;

- individual customizable set of details for a group of similar materials;

- automatic generation of names and vendor codes;

- automatic conversion of quantitative indicators into other units of measure (for example, sheet-kg-pack-pallet-sq.m etc.);

- registration of business transactions in any unit of measure acceptable for material accounting;

- registration of receipt and expenditure transactions in any currency;

- two independent prices: accounting and planned;

- special modes for calculating parameters and describing industry-specific tools and materials.

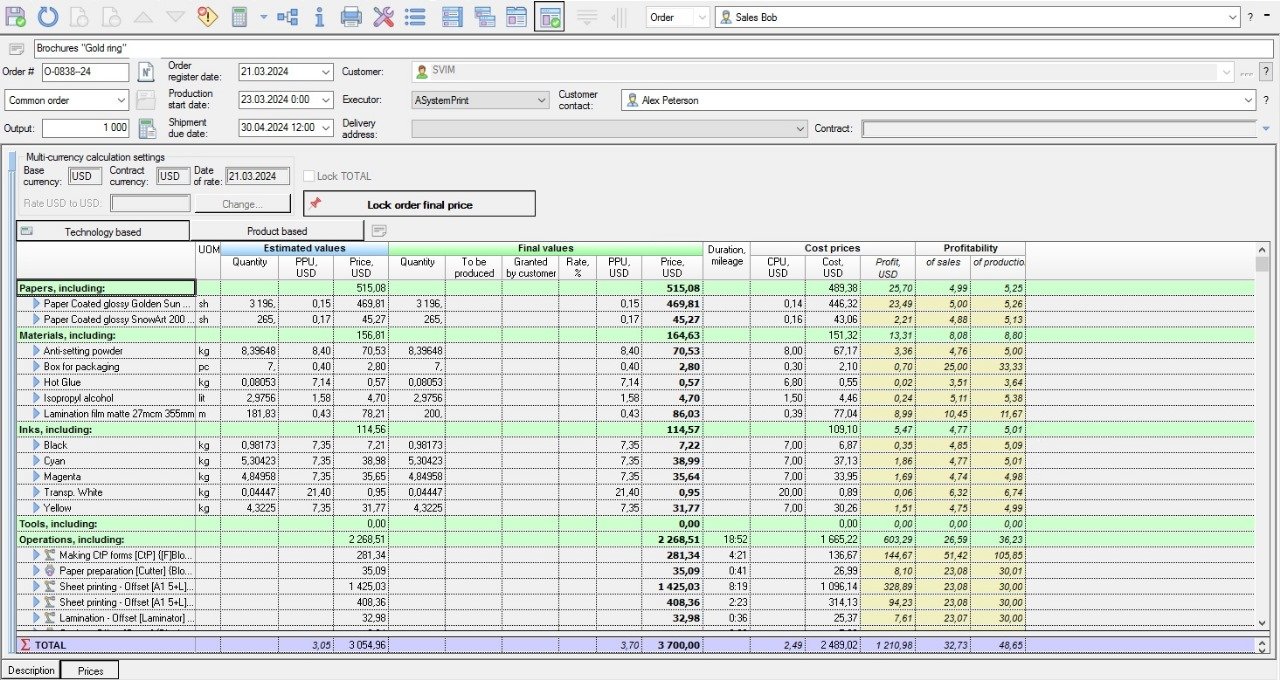

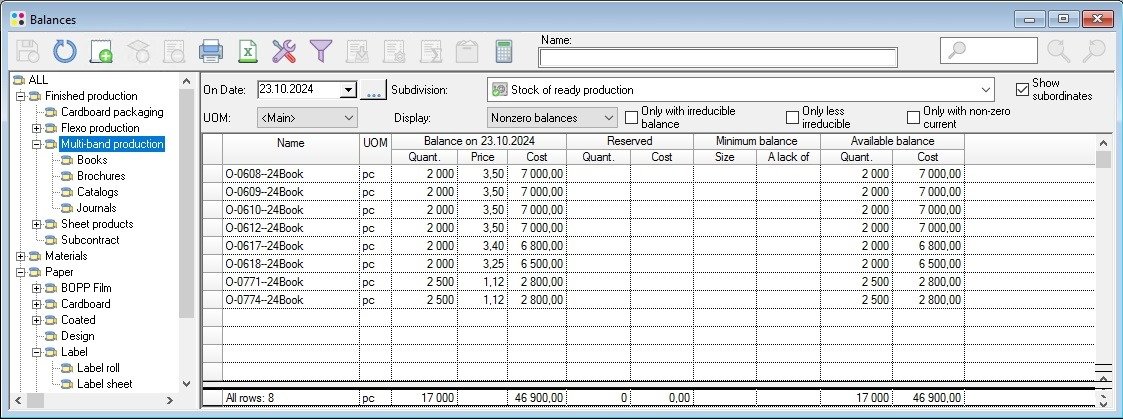

Final goods accounting

The system allows you to describe orders that result in several types of products. Accordingly, as a result of calculating such orders, both the price (cost-price) of the order as a whole and the price (cost-price) of individual products are determined. The price of an order can be calculated either on the technological basis which includes the cost of works, paper, materials and other cost items, or according to the price list for standard (or contractual) types of products.

Registration of receipt of finished products at the warehouse occurs automatically upon entering information into the system about the completion of the last technological operation of the order. Products are written-off from the warehouse when the shipping documents are issued.

PSystem allows you to correctly process practical situations that arise in the finished product warehouse, namely, excessive or deficient product output, product release and shipment in lots, etc.

Costs and Profits

Production cost is one of the key indicators of a company’s competitiveness. Typically, the term „printing production cost“ refers to the full cost of a printing order.

What is cost? Cost is the sum of expenses allocated to a cost object. For printed products, the cost object is the order.

There are several cost calculation methods. We use the „Standard Costing“ method for calculating full cost in our solutions. Briefly, the essence of this method is that cost is made up of direct costs (paper, materials, etc.) and a share of indirect costs allocated to the order.

Taking into account the specifics of production, we use the ABC cost model, adapted specifically to printing and packaging production. Activity-based costing (ABC) is a specialized cost model that identifies a company’s activities and assigns costs to each activity based on the true cost of each individual activity. This model also converts overhead costs into direct costs, unlike the standard costing model.

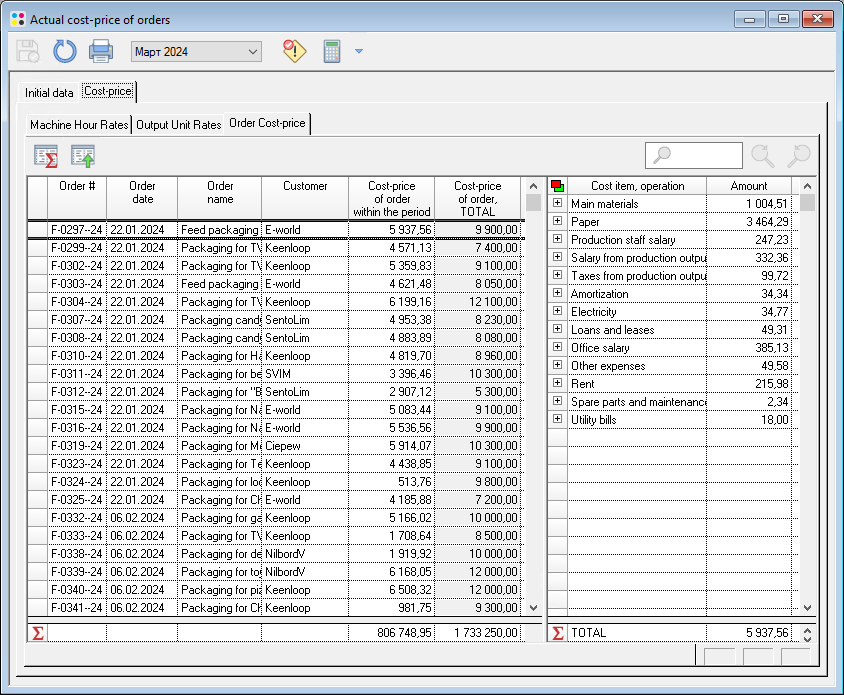

What does costing provide? Costs can be planned and actual.

Planned costs are calculated based on planned costs and the production plan. The result is used to set the selling price or to monitor breakeven when selling at the list price.

Actual costs are determined based on the actual order fulfillment. Actual costs are used for the calculation. Indirect costs are calculated monthly and allocated using the ABC method. Direct costs are allocated directly based on production accounting data.

The most interesting comparison is between planned and actual costs. Analyzing the results allows you to identify deviations, understand their causes, and make appropriate management decisions.

Advantages of our solution

- We utilize a modern management methodology for calculating the full cost of production for job-order manufacturing;

- We offer extensive cost calculation customization options;

- Both planned and actual costs are calculated;

- The actual cost of unfinished orders is calculated;

- Actual costs are collected for all reporting periods in which work was performed;

- Production efficiency analysis is based on a comparison of both quantitative and cost indicators;

- Highly detailed calculations provide extensive analytical capabilities.

Analytical Capabilities

We have developed a variety of analytical tools to evaluate the efficiency of a printing house in terms of costs and profitability. Here are some of the key ones:

- Calculation of planned cost by materials and process operations at the order placement stage;

- The results of the planned and actual cost calculations are presented to the user by cost items and cost elements;

- The ability to perform a detailed cost analysis of a completed order, down to the stages of each process operation, providing a detailed analysis of the material costs for the production of each order element;

- Order cost analysis provides data on planned and actual costs, as well as planned and actual profit. Data is grouped by product type, customer, or manager. The user’s attention is focused on unprofitable orders. For any order, a detailed cost analysis is provided by cost elements, including materials and process operations. Each process operation, in turn, is broken down into indirect cost items;

- Material cost analysis compares planned and actual material costs for production, revealing the causes of variances. It calculates additional profits and losses resulting from these variances. The results are used to adjust planned material prices and material consumption rates.

- Machine-hour cost analysis examines the impact of indirect costs and equipment utilization on labor costs. Deviations between actual results and planned indicators are analyzed. The results are used to optimize equipment schedules, adjust planned cost calculation settings, and, as a result, ensure more accurate profit planning.

- Equipment cost analysis provides data on the profit or loss incurred for each piece of equipment and explains the results, indicating the impact of various factors.

- Outsourced costs are a means of analyzing direct costs associated with subcontractor services.

Options

There are the some system additionl options:

- Printing CRM

- Actual output online recording

- Integration with accounting, prepress, CRM systems

- Integration with the Web2Print systems

- API protocols support

- Connection to the technological equipment (JDF/JMF)

Order processes online control

PSystem allows you to control the progress of orders in real time. The efficiency of information provided to users depends on the timely registration of order progress in production.

The our company offers a specialized software solution and hardware for real-time control of orders progress, PSystemTouch.

PSystemTouch is a production data registration center using a computer equipped with a touch screen and a barcode scanner. It is designed to register information on the progress of the production plan, actual output, actual duration, executors, actual material consumption and more. The software interface imitates the equipment control panel. Information on the order progress is available to system users in real time mode.

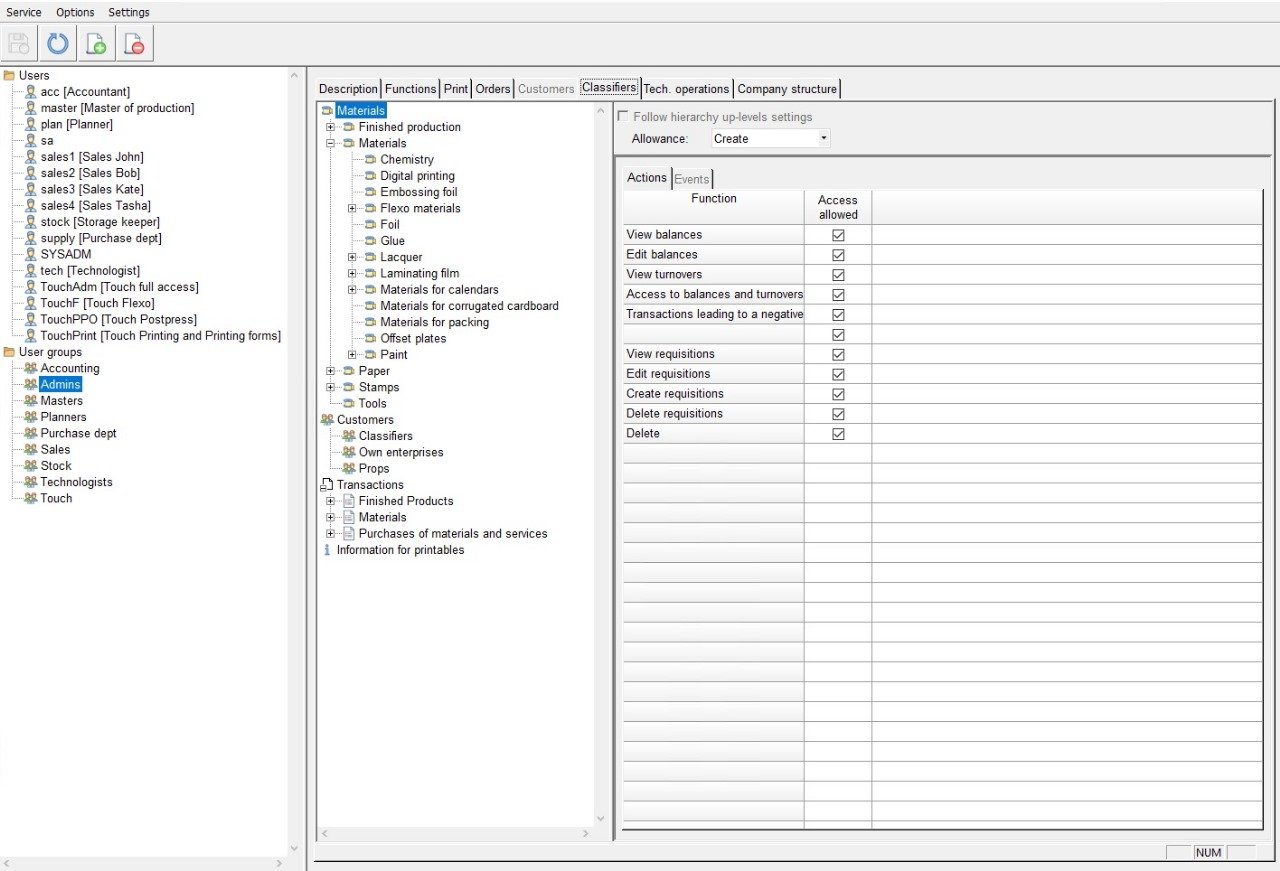

Access control subsystem

The access control subsystem solves the following tasks:

- adding/removing system users;

- changing access passwords;

- grouping users;

- managing access rights to system information and functions for user groups and individual users.

The access control subsystem allows you to regulate access to the following system functions and types of information:

- access to orders of other users;

- access to customers of other users (managers);

- access to individual order information blocks (technological, financial);

- permission to change the order states;

- access to system directories;

- access to specific document types;

- access to individual operational and analytical reports.

Reports and Analysis

- General reporting

- By product type (turnover, profit, margin etc.)

- By equipment type (utilization, profit, margin etc.)

- Settlements with suppliers and contractors

- Shipped products, work in progress

- Turnover, debt and fulfillment of sales

Operational production reporting

PSystem automatically generates operational production reports. Automation of production planning allows you to quickly prepare a package of planning documents, including:

- employee work schedules;

- order processing schedules;

- shift assignments;

- operational work plan and other reports.

Based on the actual data on order processing in production entered into the system, PSystem generates the following types of reports:

- reports on the fulfillment of the production plan per shift;

- reports on equipment loading per shift;

- reports on the work of production personnel per shift;

- reports on the actual consumption of materials and its deviation from the plan per shift;

- quality reports per shift.

Analysis of results achieved

The system generates the following analytical reporting groups:

- analysis of production indicators;

- plan/actual cost-price analysis;

- analysis of product and services sales.

Analysis of production indicators includes the following types of reports:

- plan/actual analysis of production plan fulfillment;

- equipment loading analysis;

- plan/actual analysis of paper and material consumption;

- reports on the production personnel works for a period;

- statistical processing of shift reports on quality and other reports.

Plan/actual cost analysis allows you to analyze:

- deviations in order cost-price;

- deviations in equipment operating cost;

- deviations in material cost;

- summary data on cost by product type;

- deviations in cost by orders of individual customers and orders accepted by individual managers.

Analysis of product and services sales includes:

- analytics by customers (activity, order amounts, debt);

- analytics by managers (ratio of calculated orders to sold ones, number of orders for a period, profit);

- analytics by product type (turnover, profit, profitability, work/materials ratio, etc.);

- analytics by equipment type (utilization, profit, profitability, etc.);

- analytics on mutual settlements with suppliers and subcontractors;

- analytics on shipped products and order works in progress;

- analytics on debts and fulfillment of the product sales plan.

Each group includes a set of reports that allow you to evaluate the efficiency of the enterprise in the relevant context and perform a plan/actual analysis.

The results obtained can be exported to the most common data exchange formats for further processing and analysis.